A beautiful leather and stylish frame may be the reasons you fall in love with a sofa or chair, but if you ignore what’s inside, your affections may fizzle over time.

To help consumers understand the variations in interior workmanship and materials that impact both price and durability, Jim Winkler offers tips for consumers who want to purchase the best quality within their price range.

“There is quality-constructed furniture for every budget,” says Jim Winkler, President and Founder of LeatherShoppes Inc. “Understanding interior features will help you make the best purchase in your price range.”

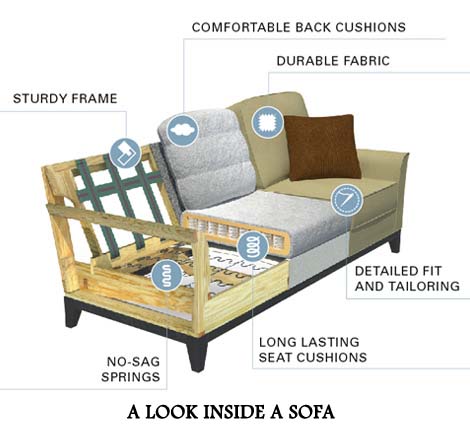

Four basic components create the comfort and durability of upholstered furniture: the frame, the supporting foundation, the cushioning and the upholstery.

The Frame

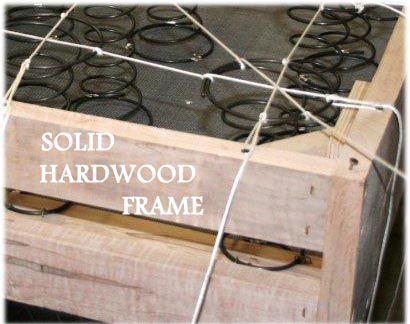

Historically, more durable frames were made of kiln-dried hardwood (photo above), such as oak, alder, birch or maple. Drying ensured the frame would resist warping, and hardwood species were preferred because they hold pegs, screws, staples and nails securely in place for a long time.

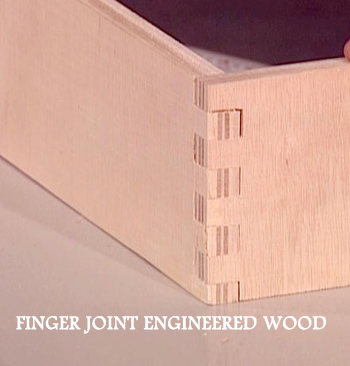

However, as a result of technological improvements over the last decade, hardwood plywood frames (photo above) are now among the most durable. Shown above finger joint plywood.

Regardless of the framing material, more durable pieces are constructed with reinforcements that are glued and screwed into place at critical joints and stress points. Less durable pieces may only staple the support blocks in place or contain no corner blocks at all.

Shopping checklist:

- Ask what materials are used in the frame.

- Make sure it feels sturdy, sits squarely on the floor, and doesn’t creak or wobble.

- Look at the underside for interior corners that are braced with corner blocks.

The Foundation- General pecking order... Best first

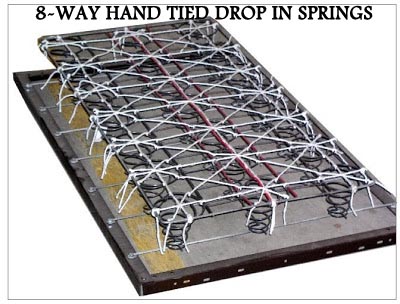

Eight-way, hand-tied, coil spring construction (photo above) was once considered the hallmark of quality upholstery. In this type of foundation, each coil spring is placed in the seat by hand and tied into place with twine in a series of interlocking knots.

Although eight-way, hand-tied coils are still a mark of fine craftsmanship, other construction techniques, including new steel spring configurations, offer equal comfort and equal or sometimes better durability. In general, the number of springs and how they are reinforced determines cost and quality.

Shopping checklist:

- Ask how the foundation is constructed.

- For more resilience, look for steel spring construction, whether coil, zigzag, (sinuous) or some other configuration like webbing.

The image above shows a drop in coil spring unit. This type of spring system is generally less expensive and labor intensive. It allows for a single cone shaped spring for support but does not provide as much "sit in" travel for comfort as a true 8-way hand tied system. This machine made unit is wired tied to hold the springs in place, an additional step is added with the string tying process to emulate an 8 way hand tied unit. The second photo deep in spring unit.

The image above shows a Sinuous or Zig Zag spring unit. This type of spring system is generally less expensive and labor intensive than a drop in spring system. It allows for a single "S" shaped spring for support but does not provide as much "sit in" travel for comfort as an 8-way hand tied system. This type of spring is used in seat frame and sometimes backs for support. This spring comes in different gauges for durability and depending on application how far apart on frame and reinforced would dictate lifespan.

The image above shows a Rubber webbing unit. This type of suspension system is generally less expensive and labor intensive than a sinuous spring system. It allows a 3-4 inch rubber strap support running horizontally and vertically on top of a frame for seat support. If used in back support a single vertical strap is commonly used although some manufactures opt of the horizontal and vertical combination. Expect this system not sit softer over time as strapping tends to stretch and not recover as it ages. The tensile strength of this system is important if used properly can provide many years of use.

Cushioning

Most upholstery cushions are made from some type of polyurethane foam. However, depending on the product’s design, the back and seat cushions may include a combination of springs, cotton or polyester fiber, foam or down.

Density is used to gauge the durability of polyurethane foam, and, generally, the higher the density the more durable (and more expensive) the cushion will be. Better quality upholstered furniture uses foam with a density rating of 1.8 to 2.5.

Foam cushions should be wrapped or covered to protect the foam from direct contact with the upholstery fabric.

Recent innovations include polyurethane foam in which 10 to 30 percent of the petroleum-based ingredients are replaced with a renewable soy-based ingredient.

Shopping checklist:

- Sit. Slump. Sprawl out! The best way to tell if the cushioning is right for you is to feel it in just the manner you’ll be using the piece at home.

- If durability is a key factor in your purchase, find out how cushions are made, including the density of foam used.

- If exposure to FR chemicals is a concern, find out if the manufacturer is using foam with no-added FR chemicals.

Cover

Options for the color, pattern and texture of your upholstery are virtually unlimited, but cover components fall into just two basic categories: natural and synthetic.

Natural components include cotton, linen, silk, wool and, of course, leather. Synthetics include acetate, acrylic, nylon, rayon and polypropylene. Many fabrics are woven with a combination of natural and synthetic fibers.

Fabrics combining a tight weave and durable fibers like nylon or polypropylene are a good choice for active use. Leather is also a popular choice for durability.

Shopping checklist:

- Ask about fabric components. Look for high percentages of durable fiber for durability.

- For very active use, look for tightly woven fabrics or leather.

One Final Consideration

For fire safety reasons, make sure new upholstery carries the gold UFAC tag. This tells you the piece was manufactured according to fire safety standards developed by the Upholstered Furniture Action Council. These standards reduce the likelihood of upholstered furniture catching fire from a smoldering cigarette, which is the leading cause of upholstery fires in the home.

No added chemicals are needed for furniture to pass the UFAC flammability tests. Flame retardant chemicals have drawn criticism in recent years. They were added to the foam supplies for upholstered furniture in order to meet stringent flammability tests. But new research in 2013 indicated these chemicals may provide little or no additional fire safety.

In addition, some states have banned products containing these chemicals because of concern over their possible adverse health impacts. Unfortunately, there is little consistency in the way states are approaching this issue, so there is also no consistency in the way upholstered products are being labeled.

American Home Furnishing Association maintains a list of manufacturers producing products with no added flame retardant chemicals to assist consumers for whom this is a priority.

“When you decide to purchase some living or great room furniture be wise and choose leather, for durability, clean ability and comfort. Get yourself some knowledge and know what you are buying. To many people make a quick decision on furniture without knowing any facts and end up replacing their furniture because of a bad decision ” Winkler concludes.